| Sign In | Join Free | My futurenowinc.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My futurenowinc.com |

|

Brand Name : SUMA

Model Number : FXM76-25NX

Certification : ISO SGS

Place of Origin : CHINA

MOQ : 1 PC

Price : USD190-USD240 PER PIECE

Payment Terms : L/C, D/A, D/P, T/T, Western Union,Paypal

Supply Ability : 1000 PCS PER MONTH

Delivery Time : 7-15 Days

Packaging Details : Carton Box / Wooden Box

Product Name : Overrunning Clutch

Material : Bearing Steel GCr15

Bore Range : 45-60mm

Torque : 1200Nm

Rotation speed : 5000RPM

Outer Dia. : 140mm

OEM : Accept

Shaft Tolearance : ISO h6 or j6

FXM.pdfFXM76-25NX 5000RPM High Overrunning Speed Gearbox Backstop One Way Clutch

Features of FXM76-25NX Overrunning Backstop Clutch

Application as

For application as backstop in installations with high speeds in freewheeling operation.

For application as overrunning clutch in installations with low speeds in driving operation.

Integrated Freewheels FXM are sprag freewheels without bearing support and with sprag lift-off X. The sprag lift-off X ensures a wear free freewheeling operation when the inner ring rotates at high speed. The freewheels FXM are used as:

Backstops

Technical Datas of FXM76-25NX Overrunning Clutch Bearing

| Item | FXM76-25NX |

| Material | GCr15 |

| Bore dia. | 45-60 mm |

| Outer dia. | 140 mm |

| Width | 35 mm |

| Torque capacity | 1200 N.m |

| Weight | 3.1 kg |

| Package | Carton box, wooden box or as your requirements |

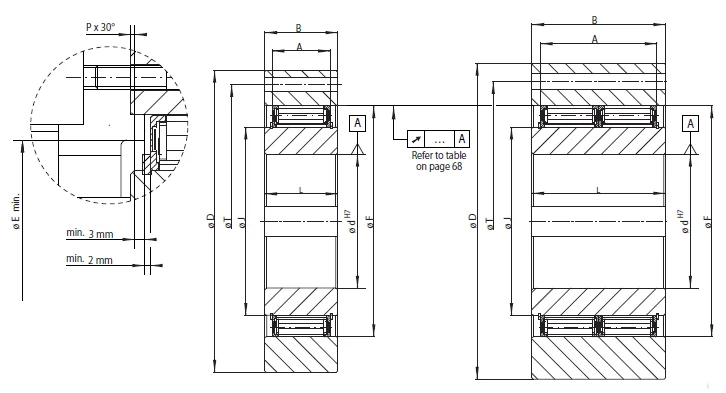

Dimensions and Capacities

Type | d | A | B | D | E | F | G | J | L | P | T | U | V | W | Z** | Weight | ||||||

| mm | ||||||||||||||||||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | ||||

| FXM 31-17 | 20* | 20* | 17 | 25 | 85 | 41 | 55 | M6 | 31 | 24 | 1,0 | 70 | 15 | 6 | 21 | 6 | 0,8 | |||||

| FXM 38 -17 | 25* | 25* | 17 | 25 | 90 | 48 | 62 | M6 | 38 | 24 | 1,0 | 75 | 15 | 6 | 21 | 6 | 0,9 | |||||

| FXM 46 -25 | 25 | 30 | 25 | 35 | 95 | 56 | 70 | M6 | 46 | 35 | 1,0 | 82 | 15 | 6 | 21 | 6 | 1,3 | |||||

| FXM 51 -25 | 25 | 30 | 35 | 36 | 25 | 35 | 105 | 62 | 75 | M6 | 51 | 35 | 1,0 | 90 | 15 | 6 | 21 | 6 | 1,7 | |||

| FXM 56 -25 | 35 | 40 | 25 | 35 | 110 | 66 | 80 | M6 | 56 | 35 | 1,0 | 96 | 15 | 6 | 21 | 8 | 1,8 | |||||

| FXM 61 -19 | 30 | 35 | 40 | 45* | 19 | 27 | 120 | 74 | 85 | M8 | 61 | 25 | 1,0 | 105 | 15 | 6 | 21 | 6 | 1,8 | |||

| FXM 66 -25 | 35 | 40 | 45 | 48* | 25 | 35 | 132 | 82 | 90 | M8 | 66 | 35 | 1,0 | 115 | 15 | 8 | 23 | 8 | 2,8 | |||

| FXM 76 -25 | 45 | 55 | 60* | 25 | 35 | 140 | 92 | 100 | M8 | 76 | 35 | 1,0 | 125 | 15 | 8 | 23 | 8 | 3,1 | ||||

| FXM 86 -25 | 40 | 45 | 50 | 60 | 65 | 70* | 25 | 40 | 150 | 102 | 110 | M8 | 86 | 40 | 1,0 | 132 | 15 | 8 | 23 | 8 | 4,2 | |

| FXM 101 -25 | 55 | 70 | 80* | 25 | 50 | 175 | 117 | 125 | M10 | 101 | 50 | 1,0 | 155 | 20 | 8 | 28 | 8 | 6,9 | ||||

| FXM 85 -40 | 45 | 50 | 60 | 65 | 65 | 40 | 50 | 175 | 102 | 125 | M10 | 85 | 60 | 1,0 | 155 | 20 | 8 | 28 | 8 | 7,4 | ||

| FXM 100 -40 | 45 | 50 | 55 | 60 | 70 | 75 | 80* | 40 | 50 | 190 | 130 | 140 | M10 | 100 | 60 | 1,5 | 165 | 25 | 10 | 35 | 12 | 8,8 |

| FXM 120 -50 | 60 | 65 | 70 | 75 | 80 | 95 | 95 | 50 | 60 | 210 | 150 | 160 | M10 | 120 | 70 | 1,5 | 185 | 25 | 10 | 35 | 12 | 12,7 |

| FXM 140 -50 | 65 | 90 | 100 | 110 | 110 | 50 | 70 | 245 | 170 | 180 | M12 | 140 | 70 | 2,0 | 218 | 25 | 12 | 35 | 12 | 19,8 | ||

| FXM 170 -63 | 70 | 85 | 90 | 100 | 120 | 130 | 63 | 80 | 290 | 200 | 210 | M16 | 170 | 80 | 2,0 | 258 | 28 | 12 | 38 | 12 | 33,0 | |

| FXM 200 -63 | 130 | 155 | 63 | 80 | 310 | 230 | 240 | M16 | 200 | 80 | 2,0 | 278 | 32 | 12 | 42 | 12 | 32,0 | |||||

| FXM 240 - 63 | 185 | 63 | 80 | 400 | 280 | 310 | M20 | 240 | 90 | 2,0 | 360 | 48 | 15 | 60 | 12 | 60,0 | ||||||

| FXM 240 - 96 | 185 | 96 | 125 | 420 | 280 | 310 | M24 | 240 | 120 | 2,0 | 370 | 48 | 18 | 60 | 16 | 95,0 | ||||||

| FXM 260 - 63 | 205 | 63 | 80 | 430 | 300 | 330 | M20 | 260 | 105 | 2,0 | 380 | 48 | 18 | 60 | 16 | 75,0 | ||||||

| FXM 290 - 70 | 230 | 70 | 80 | 460 | 330 | 360 | M20 | 290 | 105 | 2,0 | 410 | 48 | 18 | 60 | 16 | 90,0 | ||||||

| FXM 290 - 96 | 230 | 96 | 110 | 460 | 330 | 360 | M20 | 290 | 120 | 2,0 | 410 | 48 | 18 | 60 | 16 | 91,0 | ||||||

| FXM 310 - 70 | 240 | 70 | 125 | 497 | 360 | 380 | M20 | 310 | 110 | 3,0 | 450 | 48 | 18 | 60 | 24 | 135,0 | ||||||

| FXM 310 - 96 | 240 | 96 | 125 | 497 | 360 | 380 | M20 | 310 | 120 | 3,0 | 450 | 48 | 18 | 60 | 24 | 145,0 | ||||||

| FXM 320 - 70 | 250 | 70 | 80 | 490 | 360 | 390 | M24 | 320 | 105 | 3,0 | 440 | 55 | 20 | 68 | 16 | 105,0 | ||||||

| FXM 360 - 100 | 280 | 100 | 120 | 540 | 400 | 430 | M24 | 360 | 125 | 3,0 | 500 | 55 | 20 | 68 | 24 | 170,0 | ||||||

| FXM 410 - 100 | 320 | 100 | 120 | 630 | 460 | 480 | M24 | 410 | 125 | 3,0 | 560 | 55 | 20 | 68 | 24 | 245,0 | ||||||

| FXM2410-100 | 320 | 200 | 220 | 630 | 460 | 480 | M30 | 410 | 220 | 3,0 | 560 | 55 | 20 | 68 | 24 | 440,0 | ||||||

Notes:

The maximum transmissible torque is 2 times the specified nominal torque.

The theoretical nominal torque applies only for ideal concentricity between the inner and outer ring. In practice, the concentricity is affected by the bearing play and centering errors of the neigh bouring parts.

Then the nominal torques specified in the table apply, whilst taking into consideration the existing run out (T.I.R.).Higher speeds upon request.

Pictures of Overrunning Clutch Bearing

|

|

FXM 76-25NX 5000RPM Gearbox One Way Clutch Backstop Bearing Images |